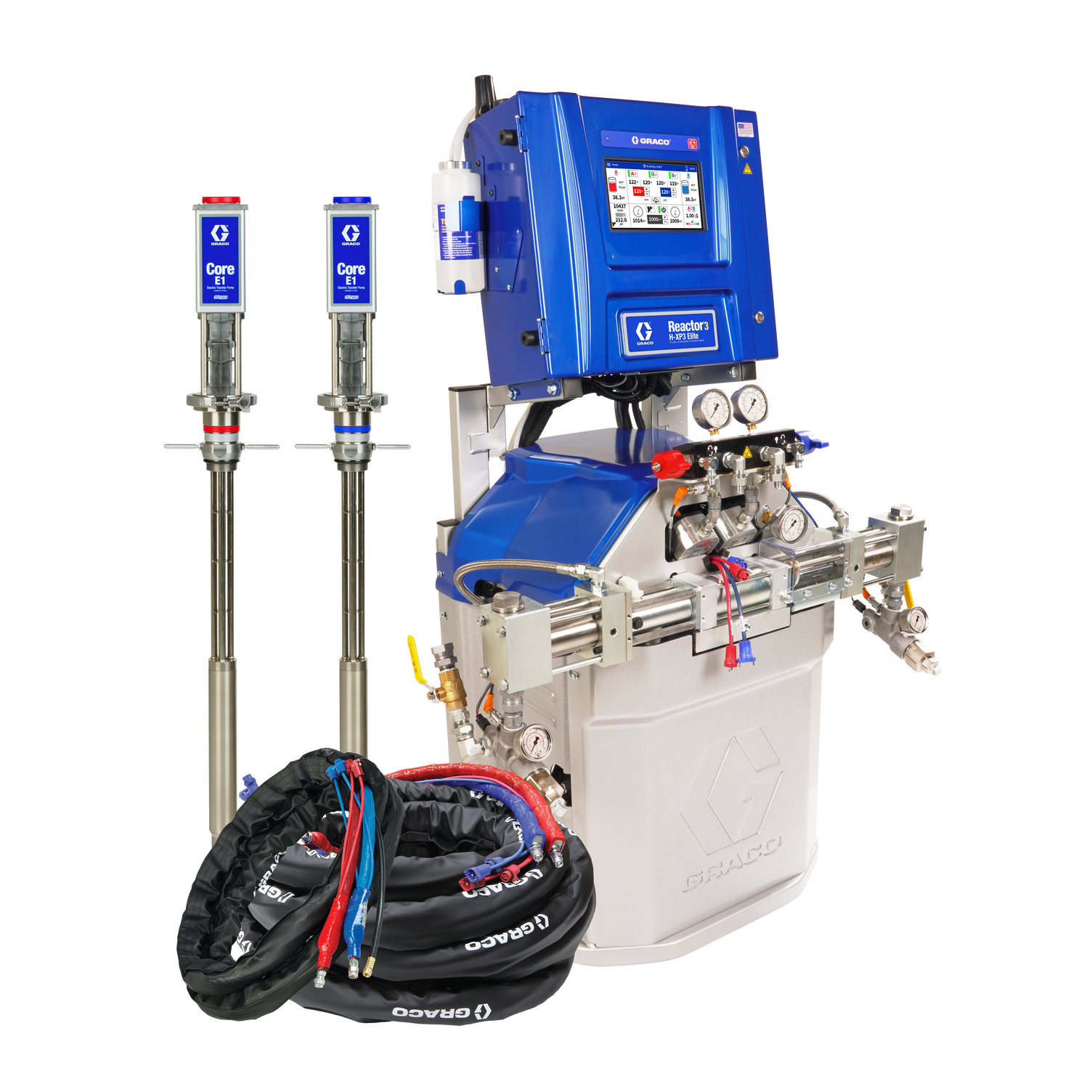

Graco Reactor 3 H-XP3

Description

Technical Specifications

Documents

The Graco Reactor 3 H-XP3 is one of the new machines in Graco's hydraulic Reactor range. The new hydraulic reactor 3 incorporates the extremely robust and high performing pump design with the advanced features of the reactor 3 controls. Specifically designed to communicate with the entire system to simplify the day to day operation, enable automatic optimisation of spray parameters and to maximise overall productivity.

The Reactor 3 H-XP3 is designed specifically with high output, high-performance, durability and reliability in mind to apply polyurea coatings to the highest quality. The ultimate machine to maximise productivity on large scale projects.

- Direct drive hydraulic pump

- The simplified design eliminates the need for a fly wheel and belt system, reducing wearing parts and therefore maintenance

- Smaller compact footprint

- Reduced noise

- Horizontal pump line

- Positive displacement pumps

- Easy to service

- A long life

- Smooth changeovers and spray pattern

- Multiple pump sizes for non 1:1 dispensing

- Hydraulic cooling system

- A powerful fan to maintain an optimal oil temperature for a longer oil life

- New touchscreen advanced display module (ADM)

- A large new touchscreen interface

- Intuitive operation and navigation

- All spray operations from one screen

- Electronic pressure control (Elite models)

- R3 hybrid heaters

- A robust heating design

- It heats materials quickly and efficiently

- Maintains temperature set points at max flow rates

- New independent hose control

- Control of A and B materials to different temperatures for improved pressure balancing and optimised yield

- Easy-access oil maintenance points

- An easy-to-access oil dip stick and oil drain valve simplifies preventive maintenance

- New inlet filters and fluid manifold

- New easy-to-maintain design

- A 2 times larger filter area

- Separate temperature and pressure sensors for more accurate temperature readings

- Redesigned with side-mounted fluid valves for easier turning and improved control

- Reactor Connect

- Real-time dashboard and reports via cellular connectivity

- Improved cellular antenna

- New GPS antenna

- GPS location available in Reactor Connect

- Job naming and reporting

- Oval gear flow meters

- Verifies fluid ratio

- Provides real-time ratio data: displayed on the ADM and Reactor Connect

- Accurate for a wide range of fluid viscosities

| Technical Specifications | |

|---|---|

| Max Pressure | 3500 PSI |

| Max Pressure | 241 Bar |

| Max Hose Length | 128M |

| Max Output | 11.4 LPM |

| Documents |

|---|